Enabling On-Demand Production at Scale.

Details:

Category:Product

Time:Apr 2020 - Feb 2021

When I first connected with Tailored Industry, they were seeking a VP of Engineering to help build the “operating system” to run their factory. As we dove into the project requirements, it was clear that Tailored needed a product manager and designer's touch more so than an engineering-first approach. This was further validated once I got to meet the founder and CEO, Alex Tschopp. Alex showed me the existing engineering prototype and some Adobe XD mockups capturing the essence of what they wanted a VP of Engineering to come in and build. I flagged a few issues off the bat. For one, there were no clearly defined "flows" -- just a series of screens showing a bunch of features that were desired. Secondly, the scope of this platform was so bloated that 90% of the features would never be seen and (I suspected) would therefore not get any use. Finally, by focusing on what could be done from an engineering standpoint rather than what should be done from a usability standpoint, the existing product scope was not maintainable or scalable.

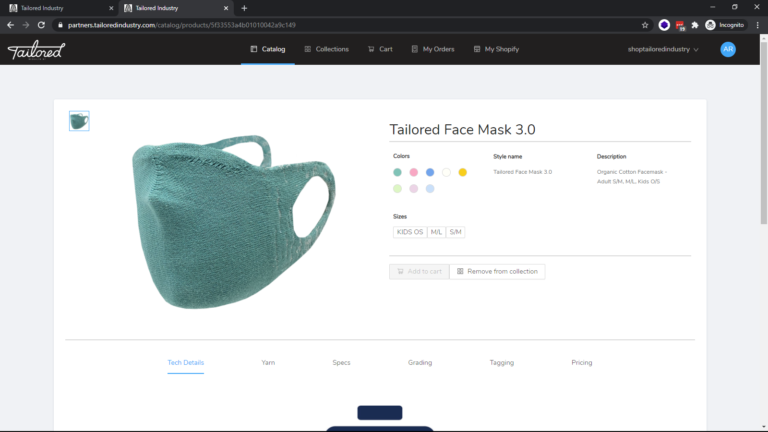

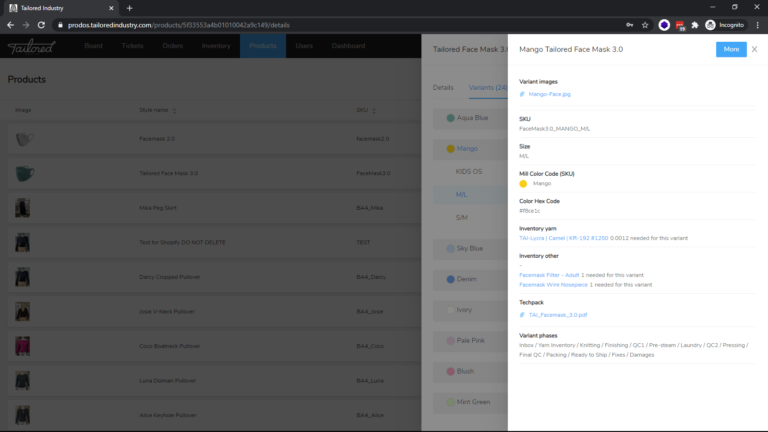

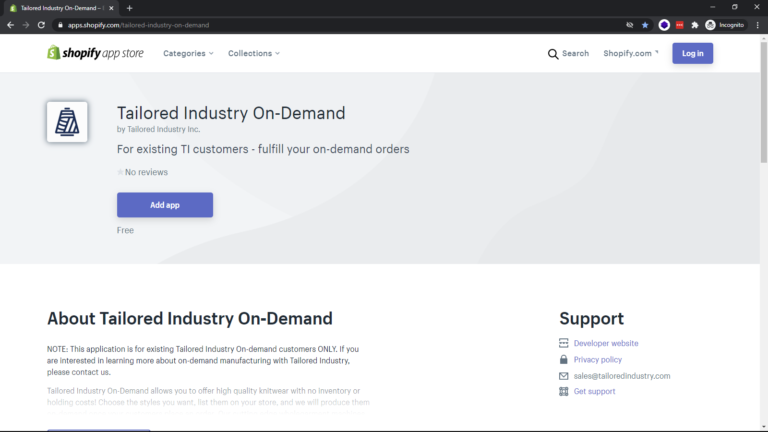

I was initially brought in by Tailored Industry to design and build its entire digital ecosystem, and subsequently stayed with the team to iterate and grow the platform. In a 4 months time span, we built and launched Production OS (ProdOS) to manage our factory operations, Brand Partner Portal (BPP) for customer facing interactions, a Shopify Marketplace App for customer integrations, and a re-designed e-comm experience.

Making On-Demand a Reality

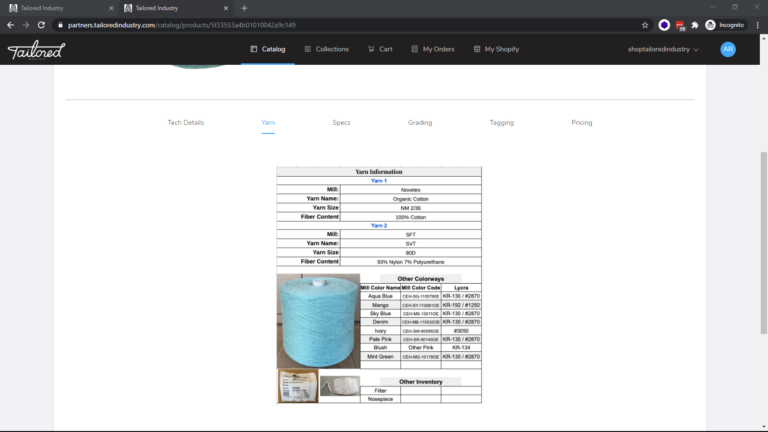

Gathering information

I kicked off our work together with a discovery and research meeting. I spent a week immersing myself in all aspects of the company and interviewing as many key employees as I could. I sliced this information by user and by view so that we could easily communicate requirements to the design team. These requirements were compiled into separate product requirements documents (PRDs) for ProdOS, Brand Partner Portal, and the Shopify Marketplace App that would tie the two together. I also consolidated redundant features to avoid showing the same information in multiple different places using multiple views. My final PRDs captured all of the relevant user stories, flows, and data entities we would be working with. These PRDs stripped down the initial scope to less than 30% of the prototype's functionality.

Design

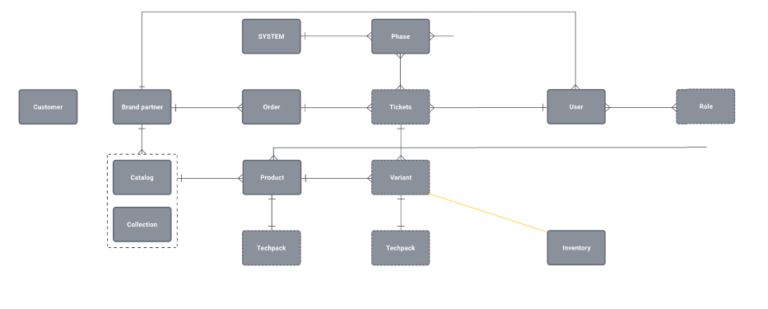

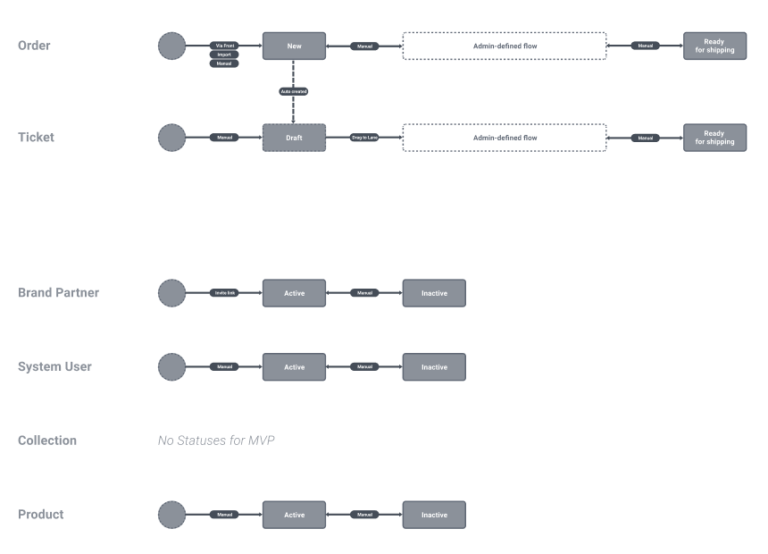

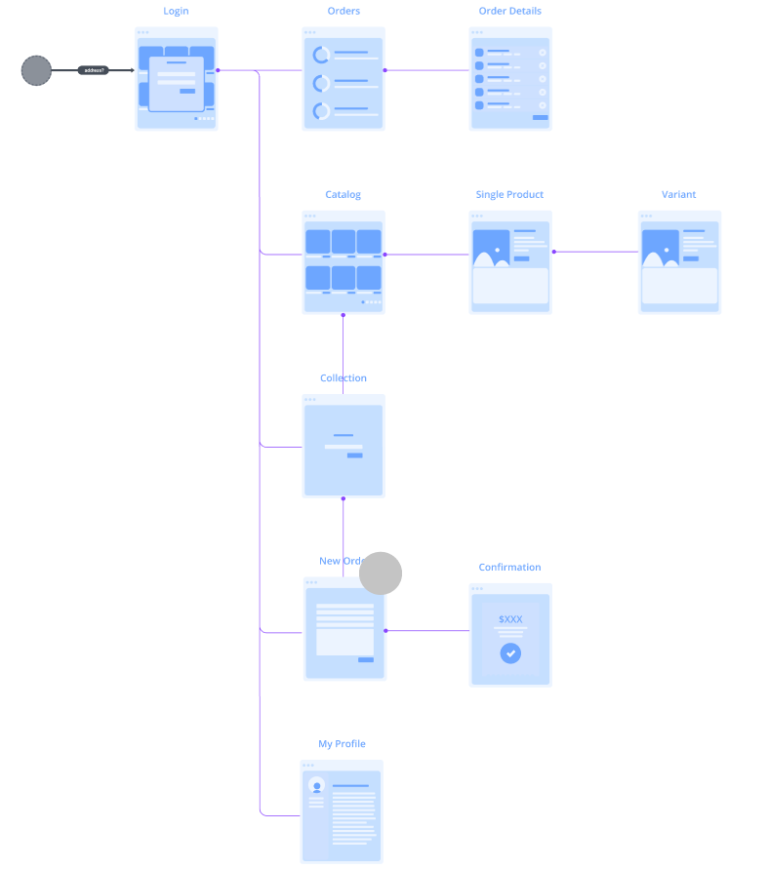

We worked with BN Digital as our design partner. After a kickoff and discovery meeting with Alec (the founder of BN) we established a top level approach and design process. First we mapped out the top level information architecture by diagramming the entities and key flows. I provided the initial drafts of these diagrams, and they were improved as a team. Once these flows were confirmed with Kady and key factory staff, we roughed the screen layouts and showed how they would flow together. After tweaking these views to match the factory staff’s expectations, we moved to a first set of mockups.

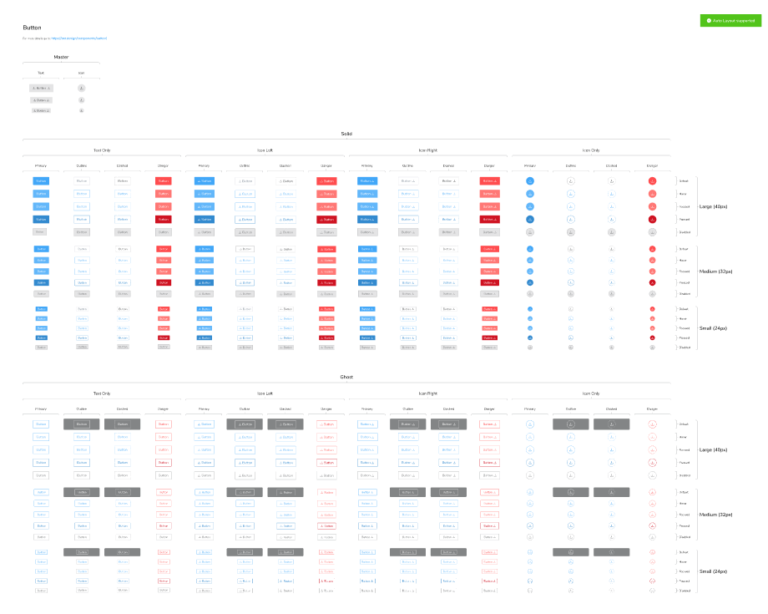

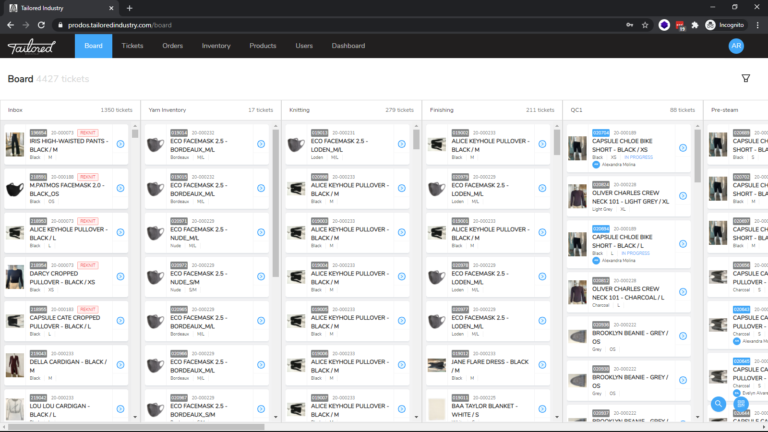

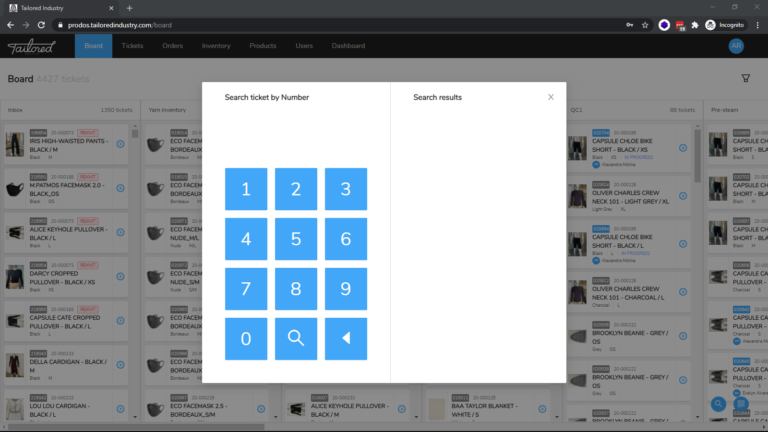

We made the decision to use Ant Design's component library as our base component library. After trying a few different design languages and UI configurations, we finally settled on a flow that uses table views for showing related entries, a sidebar for information related to a single entity, and modals for information input. Inspired by Kanban boards, our primary board view used a card and lane system. This pattern was versatile, and gave us a lot of room to expand in the future. Additionally, all of these elements worked well on the iPads used by our factory staff.

A component based approach allowed us to bypass the traditional wireframe step and move straight to medium fidelity mockups using the default Ant design components. Once we finalized layouts, we applied some basic styles. The entire process was nimble and agile; as we confirmed pages, we were able to commit them into final mockups on a rolling basis. The entire effort took about 6 weeks from start to finish.

Overall, the design process went well! Towards the end we did experience a bit of a time crunch because we deviated from our original process and made tweaks directly into the final design files as opposed to the intermediary design. There were some minor layer management and organization issues, but these were rectified pretty quickly by the BN team.

Building the First On-Demand ERP

Product Architecture

As design wrapped up, we kicked off engineering in conjunction with Alexey and his team at Dev-Better. Early on, we made some key decisions regarding the technical architecture:

- We set up a microservices architecture for this project. We knew that maintainability and continuous development were key, so we established a modular approach. We could quickly spin up and modify various services without affecting the rest of the services. Each service could run on whatever framework or language we wanted, meaning we are not globally dependent on any one stack. This also allowed for concurrent development on certain key elements which improved our speed.

- For the majority of our microservices, we chose the MERN (MongoDB, Express, ReactJS, and NodeJS) stack for this project. Mongo allowed us to expand our database entities seamlessly in the future, as we knew our initial entities would grow in scope as product requirements emerged from use on the factory floor. Express and Node gave us a robust framework and package library to work with when creating the backend logic for our core microservices. React was a natural choice for the UI given our component based approach. Together, the MERN stack gave us the versatility we needed and fit our design and product approach.

- We took a containerized approach using Docker. Our service registry was large from the start, and many services required lots of images, data, and models. Docker gave us a way to manage all of these moving parts in a manner that is easy to configure, scale, and support. In conjunction with our continuous integration / continuous development (CI / CD) pipeline via Bitbucket, a containerized approach gave us an easy to maintain, scalable system that could evolve with our needs.

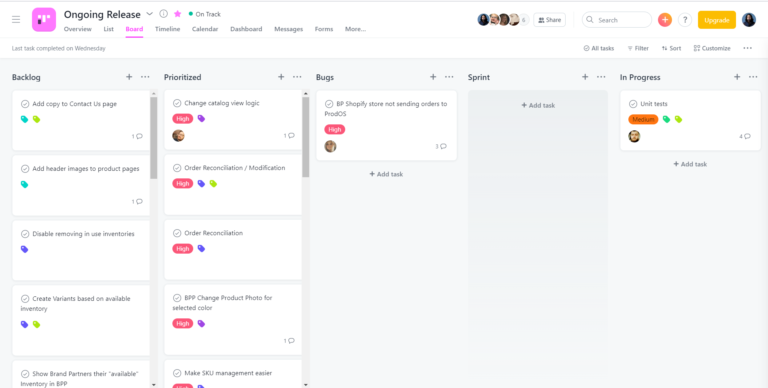

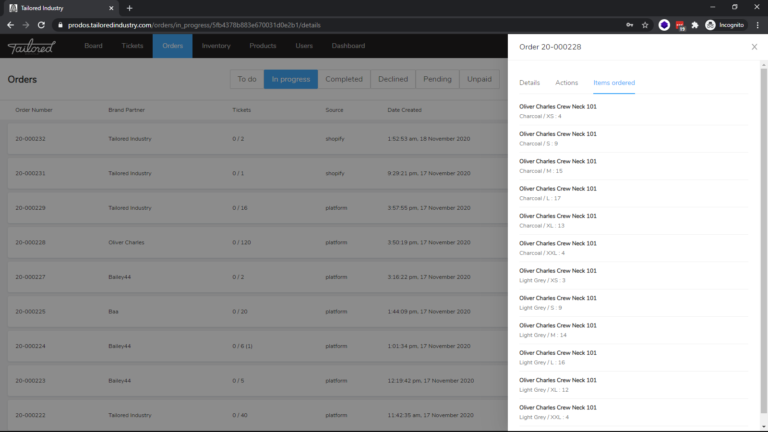

Product Management

Engineering sprints were managed in 2 week increments. We started sprints on a Wednesday, and ended sprints on a Tuesday. Demos occurred on the Friday after the end of each sprint to accommodate various schedules. We also worked hard to take a truly agile approach; after Sprint 2, we shipped working software at the end of each sprint. This was in contrast to a more common 'agilefall' approach where the MVP is treated as one large deliverable split into 4-5 sprints. We chose this approach because we wanted to verify that each use case was being adequately addressed before marking it as done. The only way to do this without losing time to a dedicated testing period was to constantly ship increments of the product and quickly test + iterate.

After 4 sprints (8 weeks) of engineering, we deployed a minimum viable product (MVP) to production on August 4th, 2020, which addressed core user stories. This MVP consisted of ProdOS v0.9, BPP v0.9, and an initial build of the Shopify Marketplace App submitted to Shopify for review.

Landing Page Development

In the 2 sprints (4 weeks) following the MVP development, we completed work on the re-designed Landing Page + Shopify store. We had started redesigning the landing page at the end of MVP development sprint 3. Our approach was to consolidate the existing ShopTailoredIndustry.com Shopify store with our TailoredIndustry.com corporate landing page. The redesigned experience unified our service offerings and corporate vision between the direct-to-consumer (DTC) and manufacturing sides of the business. The outcome tested well with our customers, advisers, and investors, and has succeeded in driving sales to both sides of the business.

Shopify App Development

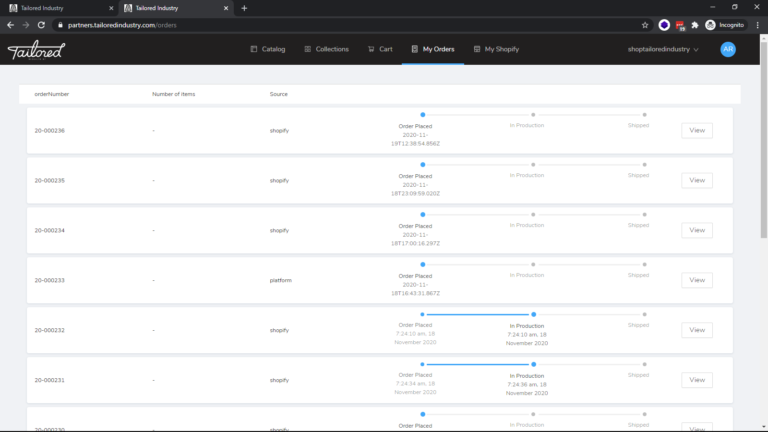

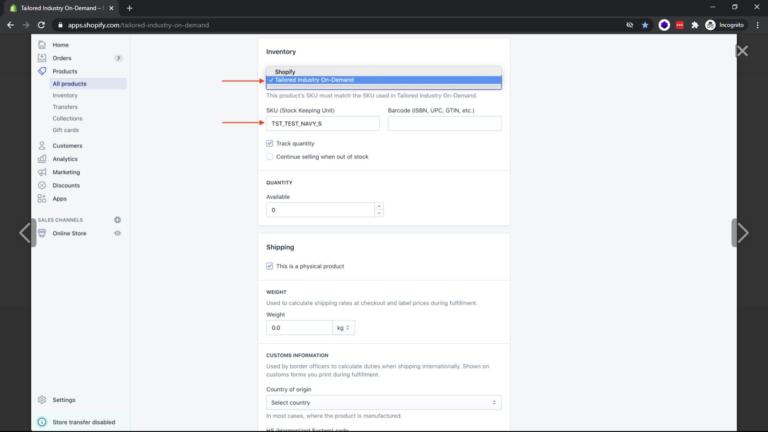

ProdOS was designed with the intention of seamlessly integrating with the Brand Partner Portal (BPP) account and our brand partner's existing Shopify stores. To connect our ProdOS and BPP platforms with our brand partner’s existing Shopify stores, we built and launched the Tailored On-Demand app via the Shopify Marketplace. This app allowed our brand partners to connect their Shopify stores to ProdOS and request fulfillment on orders which we were producing for them. These orders could then be tracked via BPP. Additionally, larger orders or sample requests could be directly submitted via BPP. Our initial submission conformed to all of the known Shopify app requirements, but was rejected due to a laundry list of hidden requirements. It took several exchanges with the Shopify internal review team to update our app per their feedback. After 4 weeks, we finally made it through the review process and were able to use the application with our company storefront. This helped us truly make on-demand manufacturing a reality.

Ongoing Iteration

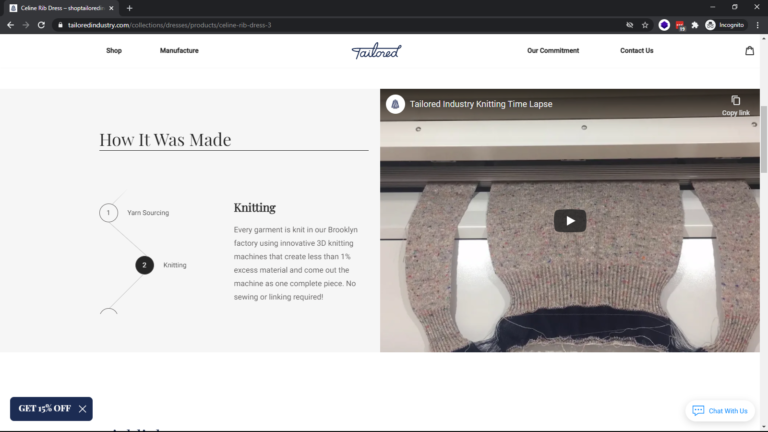

In September, we went live on all properties. Our first “customer” for the fully built out ecosystem was our own direct to consumer (DTC) line via our redesigned e-commerce store store. All of the items listed on our store had a SKU that matched up with the product’s data in ProdOS. The On-Demand app allowed us to send those products directly into ProdOS, where the order could then be approved for production. This flow gave our entire factory operation more cohesion and efficiency. The results were almost immediate - keeping track of on-demand orders was no longer a manual and laborious process, and factory planning was significantly easier.

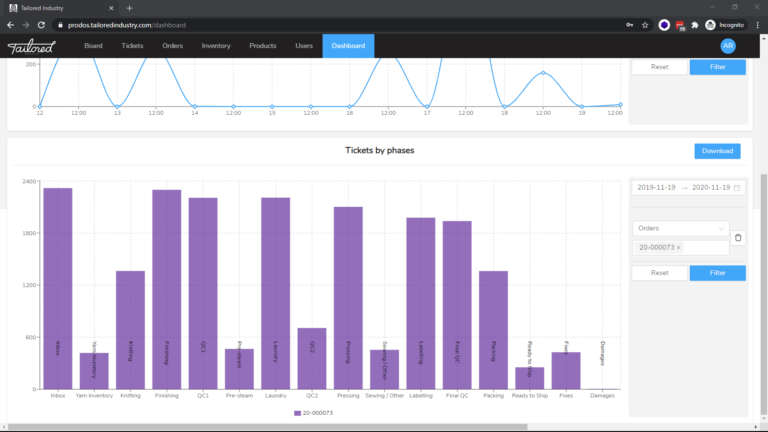

On October 19th, 2020, we officially ended the MVP phase and entered our V1.0 phase. Two months of data helped us refine the core flows and improve our entire product. Over the following 4 months, we built and launched many new features including:

- A dashboard feature which let our factory managers pull reports and review factory data.

- A ticket-to-PDF feature that allowed our factory staff to send tickets from ProdOS to a thermal printer rather than manually coupling ticket numbers in ProdOS to separately purchased physical QR tickets.

- Several quality of life updates and backend optimizations which sped up the platform and improved usability.

Final Thoughts

From the get go, I established 3 main guideposts for this product effort:

- A ticket size of 1 -- the core product thesis is enabling on-demand manufacturing by linking one digital ticket per physical garment

- ProdOS as an Employee -- treat ProdOS as an employee that the factory staff will help train.

- Yarn over pixels -- the manual process should be made easier by our digital ecosystem.

I got to present these thoughts at a brief lightning talk on November 12th, 2020. Throughout the design and development process, the team leveraged these guideposts to make sure ProdOS was addressing the right challenges for our factory staff. Tight feedback loops and timely inclusion of key stakeholders were critical to our success.

I wrapped up my role at Tailored in March 2021. The product (as it stood at that time) was well developed, running relatively smoothly, and had not experienced any major outages or bugs. As far as we know, ProductionOS is the first on-demand ERP system built specifically around a ticket size of one. I am proud of what we, as a combined team of vendors and employees, were able to build in such a short period of time. I thoroughly enjoyed my time at Tailored, and I'm proud of what we achieved as a team.